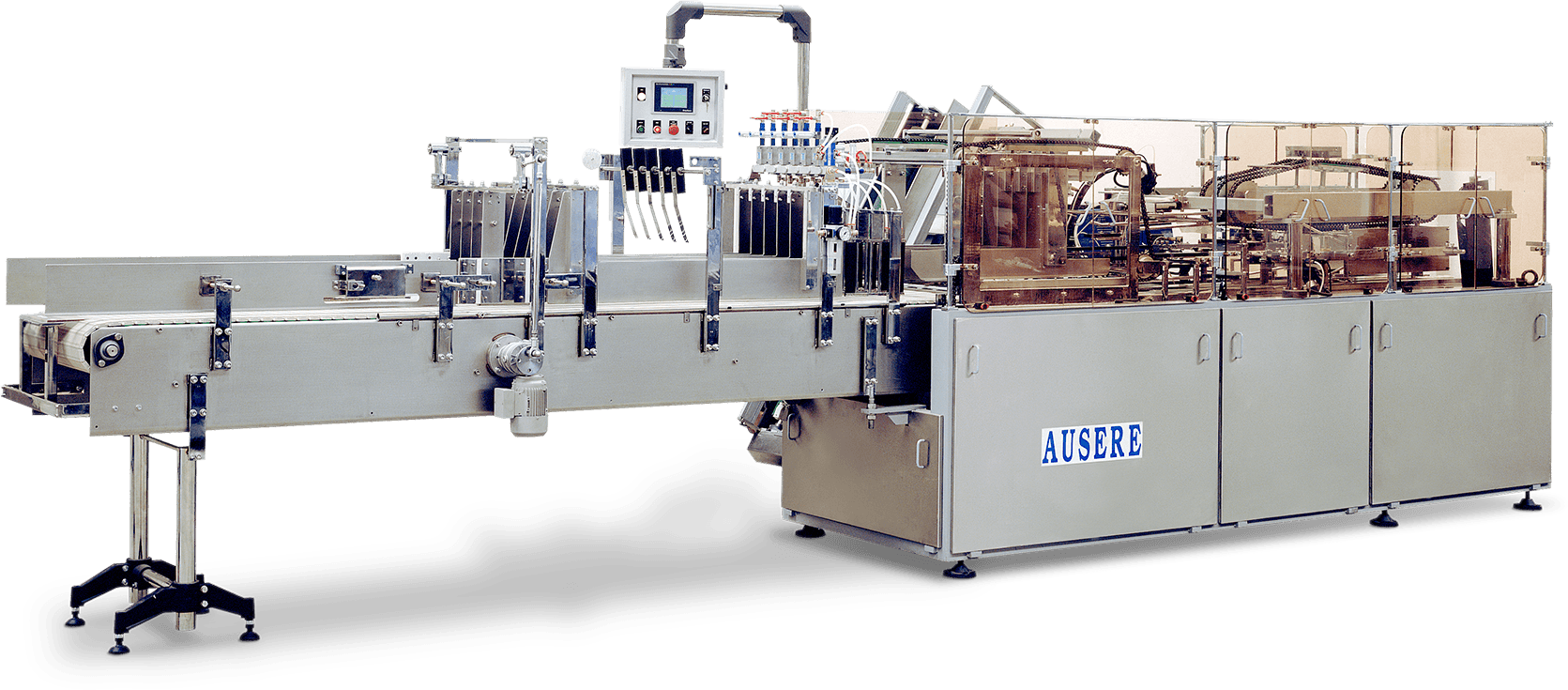

Case Packer Wrap-Around

Wrap-around system from a blank board to pack plastic or glass bottles, cans, parcels and packs of any kind.

The equipment consists of:

- Automatic infeed conveyor. Bottle conveyor to feed the wrap-around machine with bottle distributor assembly device to the machine.

- Cardboard warehouse. Electro-mechanical and pneumatic operation. The cardboard warehouse is located at 90º to gluer-former wrap-around group and it can be placed on either left or right side depending on layout design.

- Case former and sealer by hot melt to finish perfectly the full box.

Simple and efficient pneumatic system to group the objects.

Machine controlled by PLC electronic system.

Safety doors according to the CEE regulations.

| MODEL | LENGTH | WIDTH | HEIGHT | MAX. SPEED | POWER | AIR CONSUMPTION | GLUEING SYSTEM |

|---|---|---|---|---|---|---|---|

| HAM-E/90/12 | 6410 | 2000 | 2100 | 18 cases/min | 6 Kw | NL/case 10 l. |

HOT MELT |

| HAM-E/90/20 | 6900 | 2000 | 2100 | 23 cases/min | 6 Kw | NL/case 10 l. |

HOT MELT |

| CASE DIMENSION Maximum: 530 x 370 x 400 mm. Minimum: 215 x 150 x 100 mm. |

|||||||