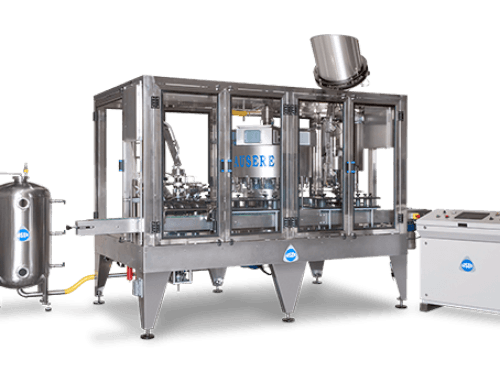

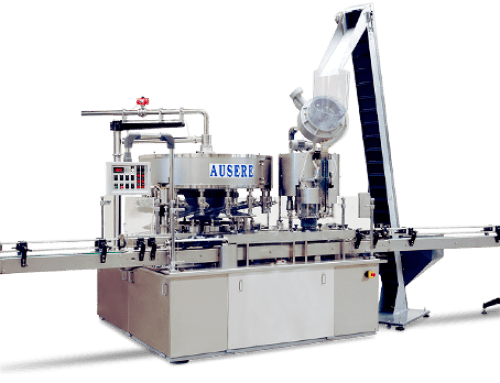

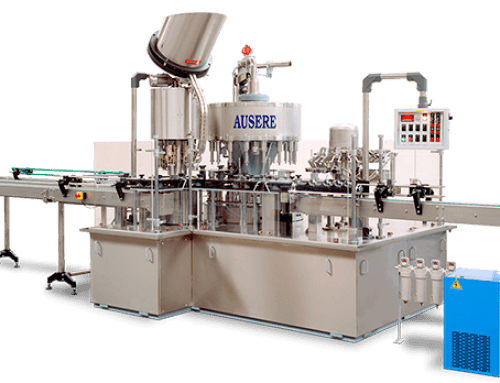

Inline Flowmeter Filler Machine mod. Ld–Ca Ausere

This is a Filler machine providing volumetric filling system with magnetic “FLOW METERS”. The volume-detecting instrument is placed before the filling valve and without any built-in obstructive parts, such providing an undisturbed flow.

Flowmeter filling allows infinitive volume range while retaining inherent accuracy.

In the Fillers Model CA the liquid, thick and viscous products arrive to the filling valves directly through the manifold and the connecting pipes with the valves, in closed circuit and with a slight pressure. Simultaneous setting of the volume to be filled for all filling stations.

The self-draining center manifold and direct distribution of product to all filling heads, combined with our pump control, reduces product change time, minimizes products losses and ensures lowest energy costs.

- Level control performed by a capacitive sensor.

- These volumetric fillers allow filling the bottles up to the top of the neck using the bottom-up system in the nozzles.

- The filling is operated in two parallel lines, while the bottles are filled in one of them, the charge and discharge the bottles is operated in the other line. Due to this is possible to eliminate the dead time for bottle transport. Very compact design. Suitable for CIP.

- Design adapts to 4, 6, 8, 10 or 12 fill heads for improved speed and fill times.

- Filler speeds from 30 to 300 bpm for most flowable products and container sizes.

| CONSUPTION | |||||

|---|---|---|---|---|---|

| MODEL | LENGTH | WIDTH | HEIGHT | ELECTRICAL | PNEUMATIC |

| LD-12-CA | 4880 | 1500 | 3125 | 4 Kw | 200 LIT/Minute |

| LD-10-CA | 4880 | 1500 | 3125 | 4 Kw | 200 LIT/Minute |

| LD-8-CA | 4320 | 1500 | 3125 | 3 Kw | 150 LIT/Minute |

| LD-6-CA | 4320 | 1500 | 3125 | 3 Kw | 100 LIT/Minute |

| LD-4-CA | 3820 | 1500 | 3125 | 2,5 Kw | 00 LIT/Minute |