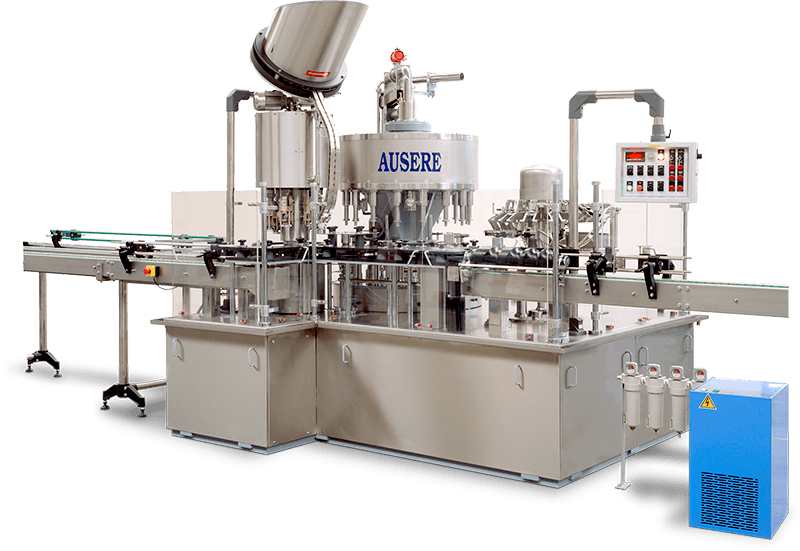

Level Filler / Capper Ausere

Fully automatic rotary filler for use in filling liquid products (WATER, VINEGAR, JUICE, etc) in GLASS and PLASTIC containers.

Gravity filling system:

Gravity/level or gravity/level in addition to vacuum system, depending on the type of liquid.

Its high capacity tank, which is built in stainless steel with the filling pipe leading directly from the tank, is located over the nozzles.

The bottles enter into the filling section using a starwheel, and are placed on the moveable supports which take the bottles up to the nozzles and fills them into the walls of the bottles so as to avoid any emulsion of the liquid.

- Holding tank, inlet tubing for liquid and nozzles are all made of stainless steel.

- Safety guard protector made of methacrylate as per the CEE regulations.

- Precise level filling.

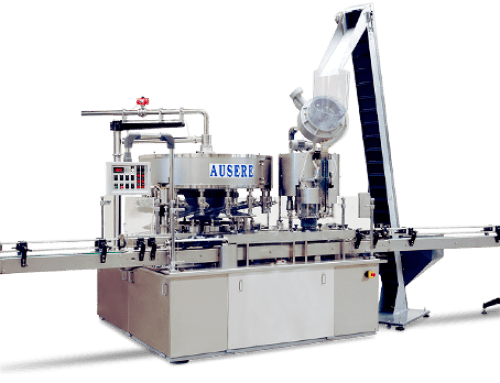

As with the previous fillers, you can also include an automatic capper for pressure, screwed or aluminium (pilfer proof) caps thus forming a MONOBLOCK with the filler, and a blowing group as a TRIBLOCK.

Optional Accessories:

- Cap Elevator

- Production monitoring program

- “No cap-no bottle” control system

- Both the capper and blower/rinser can be purchased separately

| BOTTLES / HOUR (bph) | |||||||

|---|---|---|---|---|---|---|---|

| MODEL | LENGTH | WIDTH | HEIGHT | POWER | 1 L | 1,5 L | 5 L |

| HAM-10/G | 1780 | 2005 | 3000 | 1,5 Kw | – | – | 1300 |

| HAM-16/G | 1900 | 2150 | 3000 | 1,5 Kw | – | – | 2000 |

| HAM-26/G | 2600 | 2820 | 3000 | 2,2 Kw | – | – | 4000 |

| HAM-20/V | 1200 | 1465 | 3000 | 1 Kw | 6000 | 4500 | – |

| HAM-30/V | 1500 | 1800 | 3000 | 1,5 Kw | 8500 | 7000 | – |

| HAM-40/V | 1750 | 2100 | 3000 | 1,5 Kw | 12000 | 10000 | – |

| HAM-50/V | 2100 | 2430 | 3000 | 1,5 Kw | 15000 | 12000 | – |

| HAM-12/AG/5 | 1400 | 1635 | 3000 | 1,5 Kw | – | 2500 | 1200 |

| HAM-16/AG/5 | 1670 | 1920 | 3000 | 1,5 Kw | – | 4000 | 1600 |