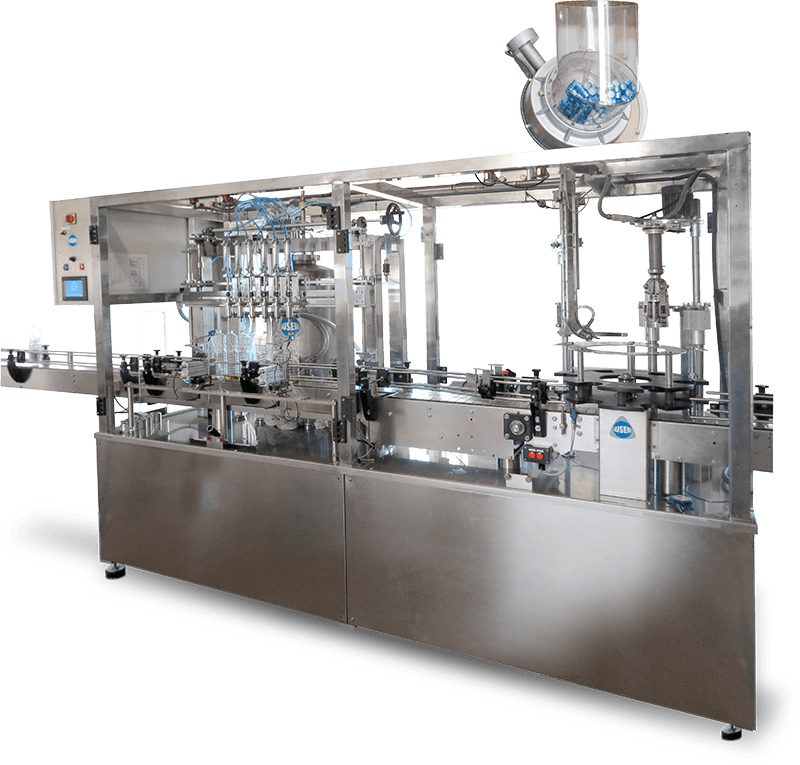

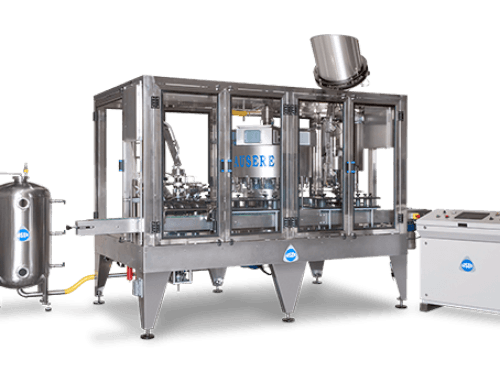

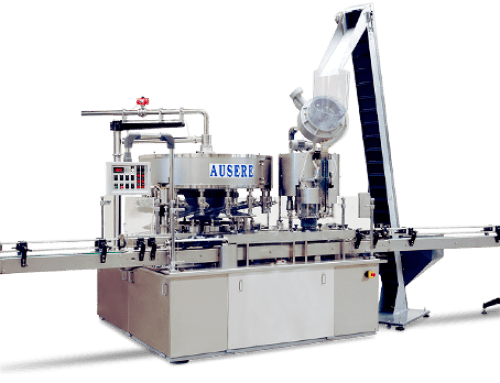

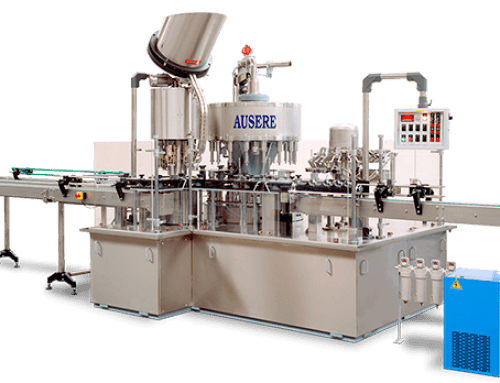

Inline Filler by Flowmeter / Capper Ausere

Fully automatic inline machine to fill viscous products (OIL) in glass, plastic, cans, etc.

Volumetric filling system by mechanical oval gears or mass flowmeters. The filling group consists of a control system and a flowmeter per each valve. The functioning of the machine is got by bottles accumulation, being adjustable the detection and blocking devices for different containers. The system works without pressure in the bottle and with slight pressure in the tank. Due to the small number of its functional parts, the filling circuit can be cleaning easily.

- Tank, inlet pipe for product and filling valves are all made of stainless steel

- Safety protections made of methacrylate following the CEE Standards.

- Maximum filling accuracy: +/- 1,5 grams per liter.

As for the closure on the bottles, an automatic capper can be mounted for pressure, screwed or aluminium (pilfer proof) caps thus forming a MONOBLOCK with the filler. The capper consists of an accumulating hopper for the caps, cap orientator, a chute and a wheel for pressure closures or a chuck head for threaded closures.

| PRODUCTION | ||

|---|---|---|

| MODEL | BOTTLES / HOUR 1 L | CARAFES/HOUR 5 L |

| HAM-4.4.5/ASM | 1.100 | 450 |

| HAM-6.6.5/ASM | 1.500 | 600 |